- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 01-27-2026 Origin: Site

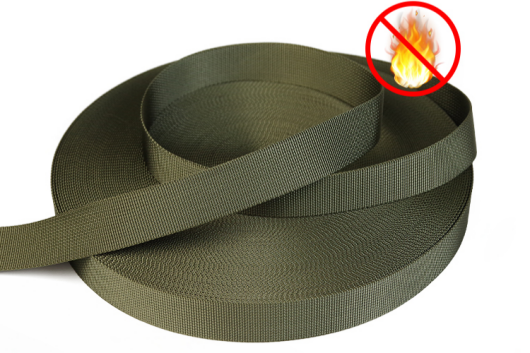

In many high-risk environments, exposure to heat, sparks, or open flames is unavoidable. From military and tactical equipment to firefighting gear and industrial safety systems, materials must perform reliably under extreme conditions. Webbing, though often seen as a minor component, plays a critical structural role. When standard webbing burns or melts, it can quickly lead to equipment failure or serious injury. This is where flame-retardant webbing becomes essential.

But what exactly makes flame-retardant webbing different, and how does it actually work?

Flame-retardant webbing is engineered to resist ignition, slow down flame spread, and reduce damage when exposed to fire or high temperatures. Unlike conventional nylon or polyester webbing, it is designed to limit combustion and, in many cases, self-extinguish once the flame source is removed.

It is widely used in applications such as:

Military and tactical load-bearing systems

Firefighter and rescue equipment

Industrial safety harnesses

Aviation and aerospace interiors

Flame-retardant webbing works through two main approaches: fiber-level resistance and chemical flame-retardant technology. The most reliable products are designed with a clear understanding of both.

Some fibers are naturally resistant to fire due to their chemical structure. These materials do not melt easily and require much higher temperatures to ignite.

Examples include:

Aramid fibers such as Kevlar® and Nomex®

Modacrylic fibers

High-performance heat-resistant polymers

When webbing is woven from these fibers, flame resistance is built into the material itself, meaning it does not wear off over time or after repeated use.

Another common method is applying flame-retardant additives to traditional fibers like nylon or polyester. These treatments are designed to interfere with the combustion process.

When exposed to fire, the treated webbing may:

Release non-flammable gases that reduce available oxygen

Form a protective char layer that insulates the material

Absorb heat and slow thermal degradation

This approach is cost-effective and widely used, though long-term performance depends on the quality of the treatment and operating conditions.

When flame-retardant webbing encounters heat or open flame, it reacts differently from standard webbing in several key ways:

Slower ignition: The material takes longer to catch fire.

Controlled flame spread: Flames spread slowly or remain localized.

Self-extinguishing behavior: Burning stops once the heat source is removed.

Reduced melting and dripping: This helps prevent secondary burns and equipment damage.

These characteristics are critical in real-world situations where even a brief delay can improve safety outcomes.

It is important to clarify that flame-retardant webbing is not fireproof. No textile webbing can withstand unlimited flame exposure without degradation.

Flame-retardant materials are designed to:

Resist ignition

Slow down burning

Reduce fire propagation

Understanding this distinction helps users set realistic expectations and choose the right material for their application.

In Western markets, flame-retardant webbing is typically evaluated according to recognized safety standards, including:

NFPA standards for fire safety

FAR 25.853 for aviation interiors

EN and ISO standards for industrial and protective equipment

Military specifications for tactical use

These tests assess burn time, char length, flame spread, and self-extinguishing performance to ensure consistent and reliable behavior.

Flame-retardant webbing works by combining advanced material selection with carefully engineered fire-resistance mechanisms. Whether achieved through inherently flame-resistant fibers or specialized chemical treatments, its purpose is the same: to reduce ignition risk, slow flame spread, and improve safety under heat exposure.

In demanding environments where failure is not an option, flame-retardant webbing is a critical safety component rather than a simple accessory. Choosing the right type—based on application, standards, and performance requirements—can significantly enhance both protection and reliability when it matters most.

content is empty!